For businesses relying on double-disc grinding machines, the decision to upgrade rather than replace them can offer significant advantages. Not only can it be more cost-effective but upgrading also reduces downtime and leverages your existing machinery’s familiarity. Plus, it’s an environmentally friendly choice, as it extends the life of your equipment and reduces waste.

This guide provides a comprehensive checklist to help you through the process of upgrading your double-disc grinding machine, ensuring you maximize performance and maintain a competitive edge.

Step 1: Assess Your Grinding Needs and Challenges

Before embarking on a double-disc grinding machine upgrade, it’s essential to understand your current grinding operations.

- Production Requirements: Consider whether your current machine can handle an increased workload or new materials that require finer finishes or tighter tolerances. An outdated machine may not meet these demands, making an upgrade necessary.

- Accuracy and Consistency: If your machine is delivering inconsistent results or struggling to meet precision levels, it might be time to consider upgrades. Ensuring accuracy is critical for maintaining quality and meeting client specifications.

- Efficiency and Throughput: Look for opportunities to speed up your grinding processes. An upgrade could lead to reduced downtime and less operator intervention, ultimately increasing your throughput.

- Safety Compliance: Ensure your machine meets the latest safety standards. If it doesn’t, identify areas where safety features could be improved to protect your operators.

- Connectivity and Integration: Modern manufacturing requires seamless data collection and integration with other workshop equipment. Your upgrades should support these needs to enhance operational efficiency.

Step 2: Exploring Custom Upgrade Options

Unsure exactly how to upgrade an old grinding machine? GCH Machinery offers a wide range of custom grinder upgrade options tailored to improve your grinder’s performance.

- Abrasive Wheels and Dressers: High-performance abrasive wheels can significantly improve material removal rates and achieve finer finishes. Automatic wheel dressers maintain consistent wheel shape, reducing the need for operator intervention.

- Spindle Upgrades: Worn-out spindles can lead to vibration and reduced accuracy. Investing in high-precision spindles enhances balancing, runout specifications, rigidity and thermal stability.

- CNC Controls and Automation: CNC control systems provide precise control over parameters, increasing repeatability and consistency. Automation features such as in-feed systems and automatic tool changers further streamline operations.

- Dust Collection Systems: Effective dust collection is crucial for maintaining a healthy workspace and extending machine longevity. Upgraded systems improve air quality and reduce a grinding machine’s maintenance needs.

- Coolant Systems: Proper temperature control is vital for grinding performance. Upgraded coolant systems with high-capacity filtration and automatic chillers enhance temperature management.

- Safety Features: Prioritize safety with features like light curtains, interlocked guards and emergency stop buttons to protect operators from potential hazards.

Step 3: Choosing the Right Upgrades for Your Double-Disc Grinding Machine

Selecting the best upgrades for grinding machines requires careful consideration of several factors:

- Compatibility: Ensure that the chosen upgrades are compatible with your existing machine. This prevents costly modifications and ensures seamless integration.

- Power Requirements: Assess your workshop’s electrical supply to ensure it can handle the increased power demands of upgraded components.

- Return on Investment (ROI): Evaluate the cost-benefit analysis of upgrades. Consider factors such as increased production output, improved quality and reduced downtime to determine the potential ROI.

Additional Considerations

There are additional factors to consider when deciding to upgrade an old double-disc grinding machine:

- Skilled Technicians: Upgrading your machine requires skilled technicians for installation and calibration. Their expertise ensures that your machine operates at peak efficiency.

- Training for Operators: New features and technologies require operator training. Investing in training ensures that your team can maximize the benefits of the upgrades.

Step 4: Partnering with a Reliable Upgrade Specialist

Partnering with an experienced upgrade specialist like GCH Machinery offers several advantages:

- Needs Assessment and Planning: GCH Machinery provides thorough needs assessment and upgrade planning to ensure that your upgrades align with your operational goals.

- Procurement and Installation: Leveraging their expertise, GCH Machinery handles procurement and installation, ensuring that each component is perfectly integrated into your machine.

- Training and Support: Comprehensive training and ongoing support ensure that your team can efficiently operate and maintain the upgraded machine.

Step 5: Implementation and Evaluation

The success of any grinding machine customization or upgrade depends on effective implementation and evaluation:

- Track Key Performance Indicators (KPIs): Monitor production output, quality, energy efficiency, downtime and operator satisfaction to assess the effectiveness of the upgrades.

- Continuous Improvement: Regularly analyze these indicators to identify areas for further improvement and refinement.

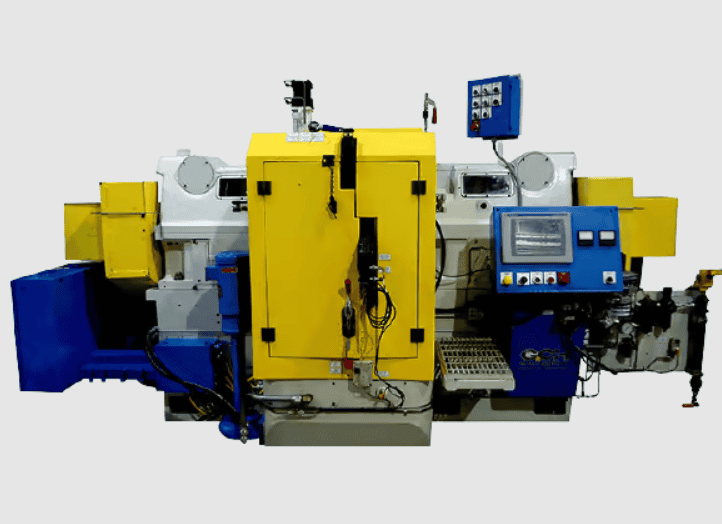

Double-Disc Grinding Machines Upgraded by GCH Machinery

GCH Machinery specializes in upgrading various double-disc grinder brands, including:

- Besly Double-Disc Grinders

- Gardner Double-Disc Grinders

- Koyo Double-Disc Grinders

- Mattison Grinders

- Giustina Grinders and more

Upgrade Your Old Double-Disc Grinding Machine with GCH Machinery

Upgrading an old double-disc grinder is a smart investment for businesses looking to enhance efficiency, quality and safety. By focusing on grinding machine parts replacement and following this comprehensive checklist, you can maximize the benefits of your upgrades and maintain a competitive edge in today’s manufacturing landscape.

For a tailored consultation and expert guidance on GCH Machinery’s grinding machine upgrades, contact us today. Revitalize your grinding operations and stay ahead in the industry.