Grinding machines play a crucial manufacturing role in numerous industries such as automotive, aerospace, medical, agricultural and mining. These machines ensure precise finishing, improved surface quality and enhanced accuracy of components. Over time, however, even the most robust grinders can experience a decline in performance due to wear and tear. This brings businesses to a critical decision point: should they replace their grinder with a new one or opt for remanufacturing?

This blog post delves into the critical decision-making process of grinder remanufacturing vs. grinder replacement, highlighting the pros and cons of each to help businesses make informed choices based on their operational needs and budget.

Understanding Grinder Remanufacturing and Replacement

Before diving into the comparison, it’s essential to understand what grinder remanufacturing and replacement entail.

Grinder Remanufacturing

Remanufacturing involves the comprehensive refurbishment of a grinder to its original specifications or better. This process typically includes disassembly, cleaning, inspection, repairing or replacing worn or damaged parts, reassembly and rigorous testing to ensure optimal performance. The end result is a machine that functions like new, often with improved capabilities and efficiency.

Grinder Replacement

Replacing a grinder involves purchasing an entirely new machine to replace the old one. While this might seem like a straightforward solution, it comes with significant costs, both in terms of money and time. Additionally, disposing of the old machine can present environmental challenges.

The Key Benefits of Grinder Remanufacturing Over a New Replacement

Cost Savings

One of the most compelling reasons to choose remanufacturing over grinder replacement is the cost advantage. Remanufacturing a grinder is typically far less expensive than purchasing a new one. This allows businesses to allocate their budget more efficiently, investing in other areas that may need attention.

Reduced Lead Time

Manufacturing a new grinder can take several months, causing significant downtime and disrupting production schedules. Remanufacturing, on the other hand, usually has a faster turnaround time, allowing businesses to get back to full operational capacity much sooner.

Environmental Sustainability

In an era where environmental responsibility is essential, remanufacturing offers a sustainable alternative to replacement. By refurbishing existing machines, businesses can reduce waste and conserve resources, contributing to a more sustainable future.

Maintained Performance

Remanufacturing restores a grinder’s performance to its original state or even enhances it. By addressing specific performance issues and incorporating modern advancements, remanufacturing ensures that the grinder operates with improved accuracy and efficiency.

Preserved Expertise

Many businesses have accumulated extensive knowledge and expertise with their specific grinder models. By choosing remanufacturing, they can leverage this existing knowledge, minimizing the learning curve and ensuring a smooth transition back to optimal performance.

Remanufacturing vs. Replacing: A Side-by-Side Comparison

To make an informed decision, it’s crucial to compare remanufacturing and replacing grinders across several key factors. Here’s a table summarizing the main differences between these two processes:

Feature | Remanufacturing | Replacing |

Cost | Significantly lower | Highest |

Lead Time | Faster | Longer |

Sustainability | Environmentally friendly | Less eco-friendly |

Performance | Restored to new or improved | New machine performance |

Expertise | Leverages existing knowledge | Requires learning new controls |

Is Remanufacturing Right for Your Grinder?

While remanufacturing offers numerous benefits, it’s not a one-size-fits-all solution. Here are some factors to consider when deciding if remanufacturing is the right choice for your grinder:

- Age and Condition: Generally, grinders with a good underlying structure and repairable components are ideal candidates for remanufacturing. Machines that are too worn out or damaged beyond repair may not be suitable for this process.

- Performance Issues: If your grinder’s performance has noticeably declined in terms of accuracy, efficiency or reliability, remanufacturing can address these concerns and restore the machine to optimal functionality.

- Availability of Parts: Remanufacturers typically specialize in specific grinder models. Ensure the company you choose has access to the necessary parts for your machine. This ensures a seamless remanufacturing process without delays due to part shortages.

- Future Needs: Consider your long-term production requirements. If your needs haven’t significantly changed, remanufacturing can effectively extend your existing grinder’s life. Even if your production demands have evolved, and you think it might be worth exploring whether a new machine with advanced capabilities, keep in mind many expert remanufacturers offer additional upgrades at a significant savings, further enhancing your machine capabilities utilizing the latest technology.

Grinder Remanufacturing – A Smart Investment

Choosing to remanufacture your grinder over replacing it with a new one is a smart investment for several reasons:

- Significant Cost Savings: Remanufacturing is more cost-effective, allowing businesses to allocate resources more efficiently and, ultimately, increase profitability.

- Quick Turnaround Time: Faster lead times mean reduced downtime and minimal disruption to production schedules, allowing businesses to meet deadlines more efficiently and maintain smooth operational flow.

- Environmental Responsibility: Remanufacturing supports sustainability by reducing waste and conserving natural resources.

- Enhanced Performance: Remanufacturing restores or significantly improves the grinder’s accuracy and efficiency, ensuring precise operations and optimal productivity.

- Leveraged Expertise: Utilizes existing knowledge of specific grinder models, allowing technicians to diagnose and address issues efficiently. This ensures a smoother transition back to optimal performance.

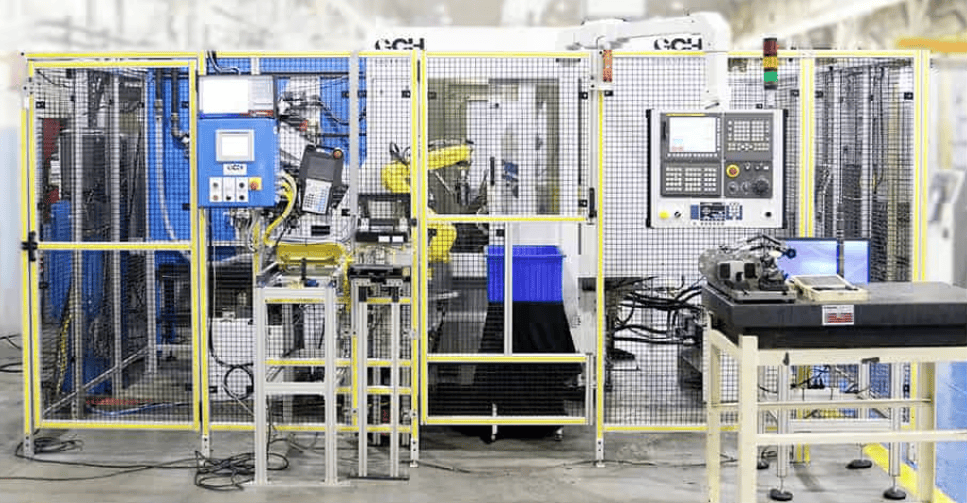

Make sure to choose a reputable remanufacturer to ensure optimal results. At GCH Machinery, we specialize in grinder remanufacturing services that restore your machines to better than new condition, often with enhanced capabilities. With over 55 years of experience, our team of experts is dedicated to providing top-notch service, ensuring your grinder operates at peak performance.

Ready to explore the benefits of remanufacturing for your grinder? Contact us today to learn more about our services and how we can help extend the life of your equipment. Don’t miss out on this opportunity to make a smart, cost-effective and environmentally responsible investment in your business.