Microcentric grinders serve as the backbone of precision manufacturing, particularly in bearing production, automotive components, and aerospace applications where tolerances measured in microns make the difference between success and failure. These sophisticated machines combine centerless grinding principles with advanced positioning systems to deliver the consistency that modern manufacturing demands.

Rather than replacing aging equipment with million-dollar investments and months of downtime, smart manufacturers are turning to grinder rebuilding & CNC upgrades as their solution. This approach combines the reliability of proven mechanical systems with cutting-edge control technology, delivering enhanced performance at a fraction of replacement costs.

The Hidden Costs of Precision Loss in Microcentric Grinders

The true cost of declining grinder precision extends far beyond the obvious scrap and rework expenses. When microcentric grinders lose their ability to hold tight tolerances, manufacturers face a cascade of financial consequences that can cripple profitability.Grinder accuracy problems have immediate operational effects. Parts that once met specifications now require additional processing or complete rejection. Production schedules stretch as operators attempt multiple passes to achieve acceptable results. Setup times increase as technicians struggle to compensate for inconsistent machine behavior.

Moreover, customer relationships suffer when delivery commitments become unreliable. Late shipments and quality escapes can damage reputations that took years to build. Competitors gain ground, meaning that struggling manufacturers lose market share to more reliable suppliers.

The ripple effects compound over time. Maintenance costs escalate as worn components create additional wear throughout the machine. Energy consumption increases as inefficient systems work harder to achieve diminishing results. Eventually, the cost of keeping problematic equipment running exceeds any perceived savings from delaying necessary upgrades.

Why Precision Declines Over Time

Grinding consistency deteriorates through predictable mechanical degradation that affects every critical component. Spindle bearings develop play that translates directly into part variation. Guide systems wear unevenly, creating positioning errors that accumulate across production runs.Hydraulic systems present particular challenges in aging microcentric grinders. Temperature variations affect fluid viscosity, creating inconsistent response times. Internal leakage reduces system pressure, compromising rapid traverse and positioning accuracy. Contamination accelerates wear throughout hydraulic components, creating a downward spiral of performance degradation.

Legacy control systems compound mechanical problems with outdated positioning logic. Stepping motor systems lack the resolution and feedback necessary for modern tolerance requirements. Open-loop controls cannot compensate for mechanical wear, allowing small errors to become major precision problems.

Thermal management becomes increasingly problematic as machines age. Worn components generate excess heat, affecting dimensional stability. Inadequate cooling systems struggle to maintain consistent temperatures across critical areas. These thermal variations create expansion and contraction cycles that further compromise grinder accuracy.

Rebuilding Your Microcentric Grinder: Restoring Core Performance

Grinder remanufacturing services begin with comprehensive inspection and analysis of all critical systems. Experienced technicians evaluate mechanical, hydraulic, pneumatic, electrical, and coolant systems to identify worn components and potential failure points. This thorough assessment ensures that rebuilding efforts address the root causes rather than just the symptoms.The rebuilding process systematically restores each system to original specifications or better. Spindle assemblies receive new bearings with improved sealing and lubrication. Slide systems get precision-ground ways and updated linear guides. Hydraulic components are rebuilt or replaced to eliminate internal leakage and inconsistent response.

Modernizing microcentric grinders through rebuilding extends machine life significantly while improving reliability. New components often exceed original equipment specifications, providing better performance than when the machine was first installed. This restoration approach delivers decades of additional service life at approximately 30%–40% of new machine costs.

The rebuilding process minimizes production disruption through careful planning and efficient execution. Machines can often be rebuilt on-site, eliminating transportation risks and reducing downtime. Modular approaches allow phased upgrades that keep production running while improvements are implemented.

How Do CNC Upgrades Improve Precision & Repeatability?

As one of the overall benefits of grinder rebuilding, CNC control upgrades for grinders transform legacy machines into modern precision manufacturing centers. Advanced controllers replace outdated stepping motor systems with closed-loop servo positioning that provides micron-level accuracy and real-time feedback. These upgrades eliminate the positioning errors that plague older hydraulic and mechanical systems.Modern CNC systems offer unprecedented control over grinding processes. Variable speed drives optimize cutting parameters automatically, adjusting to material variations and wheel condition changes. Adaptive control algorithms maintain consistent surface finishes regardless of part-to-part variations. Programmable cycles reduce setup time while improving repeatability.

CNC upgrades prepare machines for future manufacturing challenges by providing connectivity and data collection capabilities. Integration with plant-wide systems enables predictive maintenance, process optimization, and quality tracking. These capabilities position upgraded machines as integral components of Industry 4.0 manufacturing strategies.

The automation possibilities expand dramatically with modern CNC controls. Automatic tool and wheel changing, part loading and unloading, and process monitoring become feasible upgrades. These automation features reduce labor requirements while improving consistency and throughput.

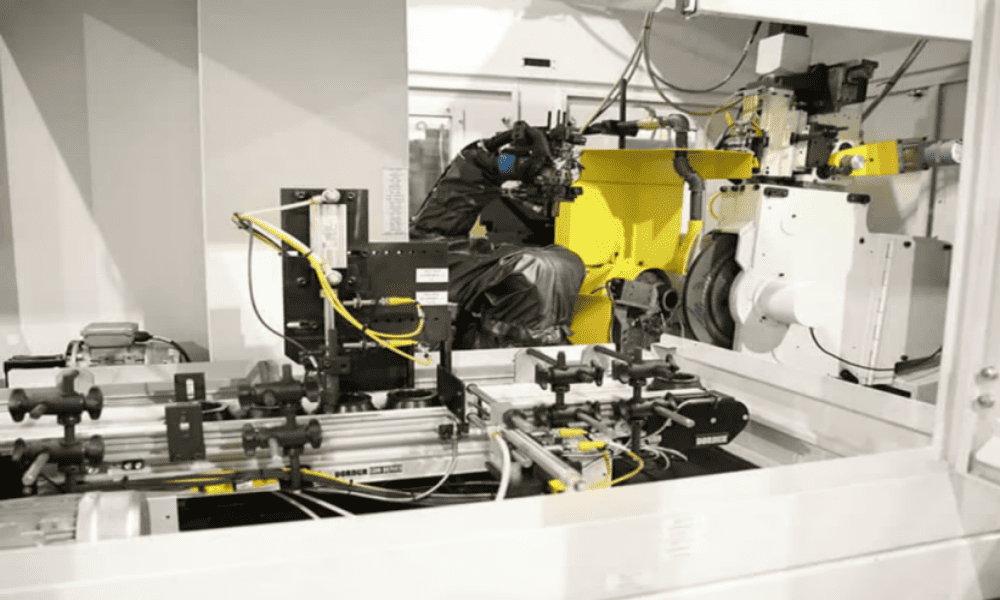

Case Study: Servo Rock – Transforming Microcentric Grinders

Now, let’s look at a case study involving a client of GHC Machinery.A major global bearing manufacturer operating high-volume production lines with legacy Cincinnati microcentric grinders faced mounting precision challenges. The client sought a modernization solution to improve precision and reduce downtime without replacing their entire fleet of proven machines.

The Challenge

The existing grinders relied on hydraulic rapid advance and stepping motors for final positioning—systems that limited repeatability and made tight tolerances difficult to maintain. Temperature variations affected hydraulic response times, while stepping motor resolution proved inadequate for modern bearing specifications.

The client needed grinder retrofitting that would:

- Improve positioning accuracy to sub-micron levels

- Eliminate hydraulic variability and temperature sensitivity

- Extend machine life through reduced component wear

- Minimize disruption to existing production schedules

The GCH Solution

GCH Machinery engineered a comprehensive mechanical and control retrofit that addressed both positioning accuracy and system reliability. The grinding machine upgrade solutions included the following:- Servo-driven ball screw assembly replaced the problematic hydraulic rapid advance system, providing consistent positioning regardless of temperature or load variations. This mechanical upgrade eliminated the variable response times that plagued the original hydraulic system.

- Closed-loop servo positioning replaced the stepping motor final positioning system, delivering micron-level accuracy with real-time feedback. The servo system provided the resolution and repeatability necessary for modern bearing manufacturing tolerances.

- Reconfigured machine architecture supported new drive components while maintaining the proven mechanical foundation. This approach preserved the machine’s fundamental grinding capabilities while upgrading critical positioning systems.

- Full integration with existing grinder frameworks minimized mechanical modifications while maximizing performance improvements. The retrofit enhanced capabilities without requiring operators to learn entirely new machine operation procedures.

Results: The Servo Rock Difference

Customer satisfaction led to additional orders, with GCH Machinery being awarded contracts for over 30 additional Cincinnati microcentric grinders for retrofit and upgrade. This scalable success demonstrated the viability of grinder upgrades as an alternative to complete machine replacement.

The Servo Rock project established GCH’s reputation as a trusted partner for precision grinding solutions and scalable retrofit programs. It proved that strategic upgrades could transform aging equipment into world-class manufacturing assets.

Restore Precision, Reduce Risk, & Maximize ROI

Grinder rebuilding & CNC upgrades solve the critical problems that plague aging precision grinding equipment: downtime, accuracy loss, escalating costs, and technological obsolescence. This hybrid approach combines the reliability of proven mechanical systems with the precision of modern control technology.

The cost-versus-risk analysis strongly favors rebuilding and upgrading over replacement. Here’s a breakdown:

Buying New Equipment:

- Capital cost: $800,000–$1,500,000+

- Lead time: 12–18 months

- Production risk: Complete downtime during installation

- Learning curve: Extensive operator retraining required

- Unknown performance: New equipment may have teething problems

The Hybrid Rebuilding Approach:

- Capital cost: $245,000–$450,000

- Lead time: 22–33 weeks

- Production risk: Minimal downtime with proper planning

- Learning curve: Familiar operation with enhanced capabilities

- Proven performance: Combines known mechanical reliability with advanced controls

As you can see, the financial advantages extend beyond initial capital savings. Reduced lead times mean faster return on investment and maintained market position. Lower risk profiles protect production schedules and customer relationships. Enhanced capabilities often exceed new machine specifications while preserving operator familiarity.

Contact GCH Machinery today to learn more about the impact of grinder rebuilding & CNC upgrades on precision and, in turn, your manufacturing investment. Let’s talk about how our team can transform your aging grinders into modern precision manufacturing centers.