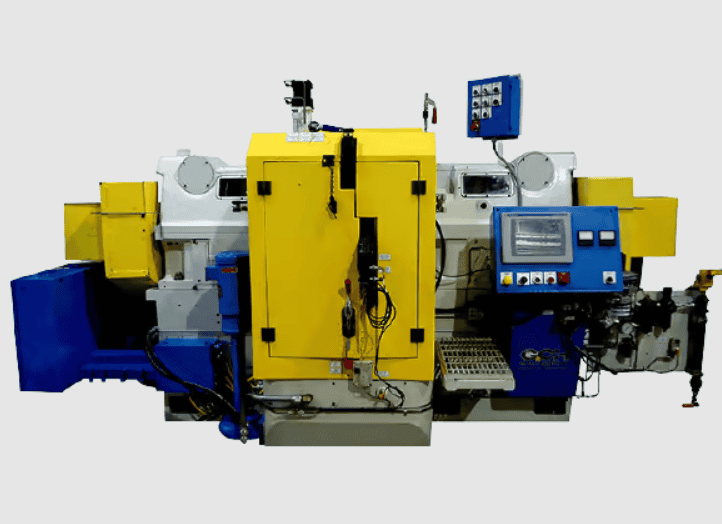

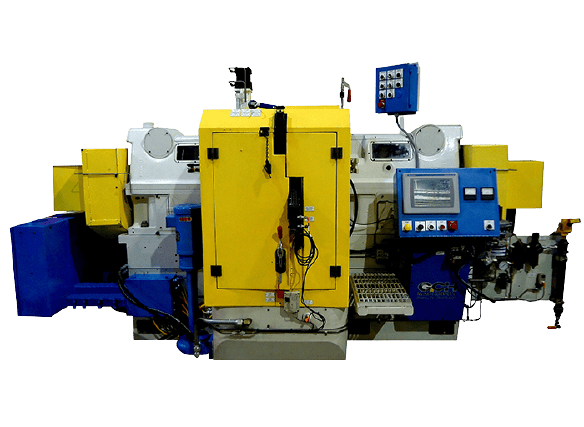

The Besly DV2 double-disc grinder has long been recognized for its reliability and precision in high-volume production environments. However, like all machinery, wear and tear can affect its performance over time. This aging process often leads to challenges such as diminished grinding accuracy, inefficiency and costly repairs, leaving business owners faced with a critical decision: replace or remanufacture?

This blog delves into how Besly DV2 grinder remanufacturing can help you achieve peak performance without needing a full replacement. Learn why remanufacturing is the smarter option and gain insights into the expert remanufacturing process.

Why Remanufacturing Your Besly DV2 Grinder Is the Smart Choice

Restore Precision and Efficiency

Aging components in the Besly DV2 grinder can lead to a decline in grinding accuracy and efficiency. Here’s how remanufacturing reverses these issues:

- Component Replacement: Key parts like spindle bearings, grinding wheels and hydraulic systems are replaced to restore grinding precision.

- Upgraded Controls: New CNC controls and automation systems are added to enable seamless operations, reducing operator intervention and improving consistency.

- Enhanced Calibration: Through precision calibration, feed rates, tolerances and grinding accuracy are fine-tuned for optimal performance.

By addressing performance issues with remanufacturing, businesses can enjoy improved throughput and reduced defects in their production lines.

Reduce Costs Without Compromising Performance

Purchasing a new grinder can be a significant financial investment. On average, a remanufactured Besly DV2 grinder provides the same level of performance as a new machine but at a fraction of the cost. Businesses can achieve:

- Immediate Savings: Upfront cost reductions of up to 60%.

- Enhanced Capabilities: Improved machine performance with custom upgrades, including energy-efficient components and faster operation cycles.

Extend Machine Lifespan

Remanufacturing your Besly DV2 grinder doesn’t just fix existing issues; it extends the operational life of your machine by 15–20 years. This long-term advantage ensures fewer breakdowns, predictable maintenance schedules and sustained operational efficiency, keeping your production running smoothly.Expert Remanufacturing Process for Besly DV2 Grinders

At GCH Machinery, our expertise in Besly DV2 grinder remanufacturing guarantees that each project is handled with precision and care. Here’s how the process works:Step 1 – Comprehensive Inspection and Disassembly

The process starts with a rigorous inspection to identify any issues, assessing critical components such as spindle bearings, guideways, hydraulic systems and lubrication systems. Once a detailed diagnosis is complete, the grinder is completely disassembled to ensure every component is addressed.Step 2 – Component Replacement and Upgrades

Outdated or worn parts are replaced with high-quality components, such as spindle bearings and grinding wheels, servo motors and CNC controls and coolant and filtration systems. GCH even offers optional Besly DV2 grinder upgrades, including advanced automation, energy-efficient systems and enhanced operator controls that improve precision and reduce cycle times.Step 3 – Reassembly and Precision Calibration

The final step ensures that your remanufactured grinder is ready for peak performance. This involves careful reassembly and precision calibration to fine-tune feed rates, tolerances and grinding accuracy. Every GCH machine undergoes rigorous testing to ensure it exceeds original specifications.Key Benefits of Remanufacturing with GCH Machinery

Minimize Downtime and Boost Productivity

Remanufacturing a Besly DV2 grinder offers quicker turnaround times compared to ordering a new machine, ensuring production disruption is minimal and boosting overall productivity.Improve Sustainability with a Greener Solution

Remanufacturing supports environmental sustainability by reducing industrial waste and conserving resources, offering a greener approach to industrial operations.Custom Solutions for Your Production Needs

Every manufacturing operation is unique, and so are its requirements. GCH Machinery offers tailored grinder retrofits and upgrades to enhance your machine’s throughput, precision and automation, ensuring it aligns perfectly with your production goals.Get More Out of Your Besly DV2 with Expert Remanufacturing

Choosing to remanufacture your Besly DV2 grinder not only restores its performance but also ensures long-term value for your business. With expert services from GCH Machinery, you can leverage cost savings, retain your trusted equipment and enhance operational efficiency with minimal disruption.To unlock the full potential of your Besly DV2 grinder, contact us today and explore our bespoke remanufacturing solutions. Transform your machinery into a powerhouse of productivity and precision.

*Required fields

*Required fields

*Required fields

*Required fields

*Required fields

*Required fields

*Required fields

*Required fields