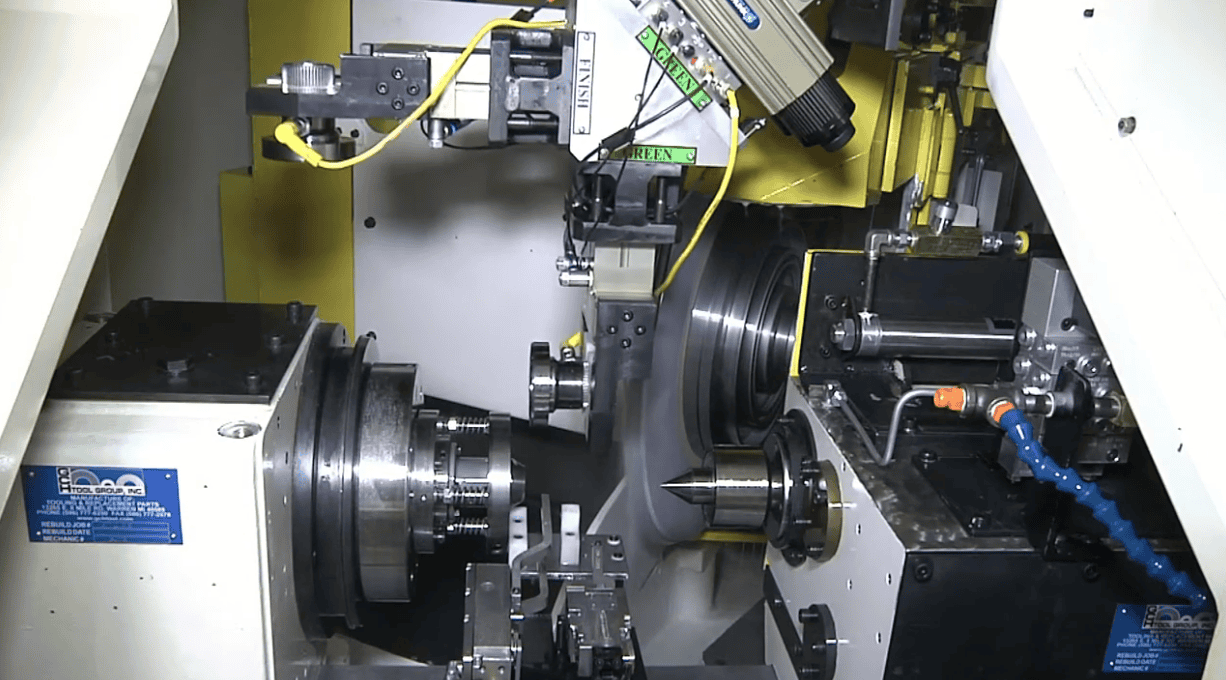

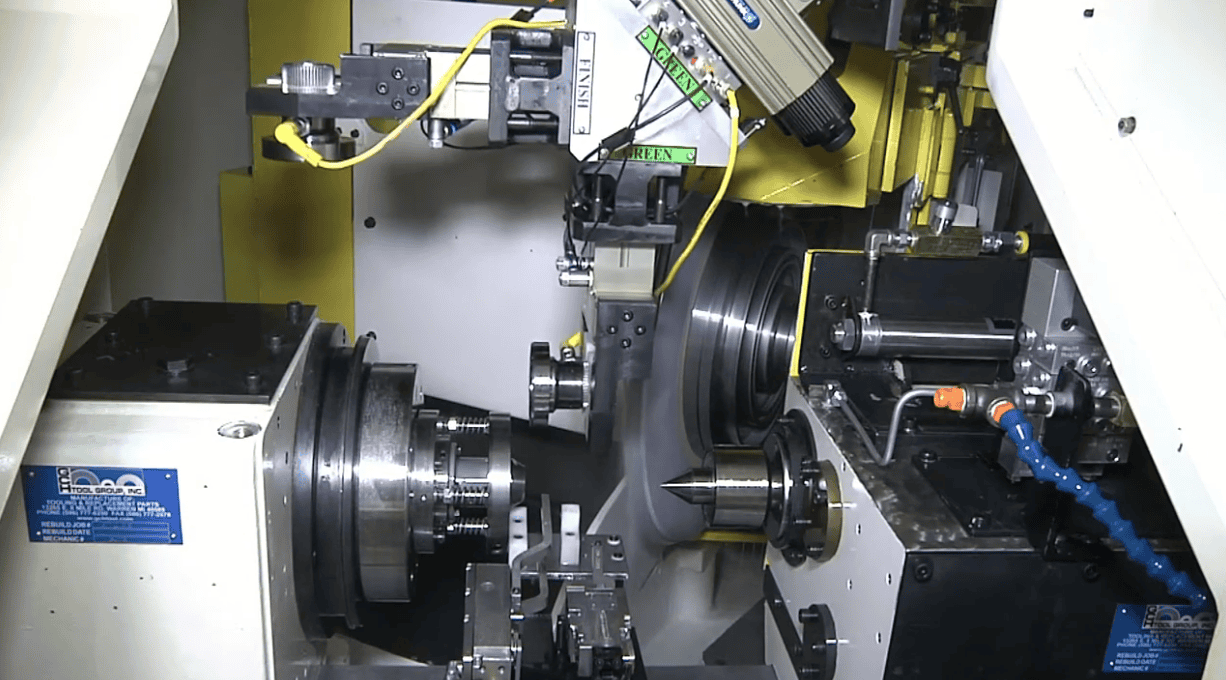

Grinding machines, like the Toyoda GL-6A, are the backbone of precision manufacturing. Over time, these machines can experience wear and reduced efficiency. However, remanufacturing by trusted professionals such as GCH Machinery offers an effective and sustainable way to restore your machine to peak performance. By partnering with GCH Machinery, you can extend the lifespan of your Toyoda GL-6A, improve reliability, and save money while benefiting from another decade of precision grinding.

1. Restoring Peak Performance

Remanufacturing through GCH Machinery involves comprehensive disassembly, inspection, and reassembly of your Toyoda GL-6A. Their expert technicians restore each component to its original factory specifications—or even upgrade the machine with modern advancements. This ensures:- Precision Grinding Resumed: With GCH Machinery’s expertise, your machine will operate with the accuracy and efficiency of a brand-new model.

- Enhanced Component Performance: Worn-out parts are replaced with high-quality alternatives, ensuring seamless operation.

2. Saving Money

Investing in GCH Machinery’s remanufacturing services is significantly more cost-effective than purchasing a new grinding machine. Key financial benefits include:- Reduced Upfront Costs: Avoid the expense of buying a new machine while achieving comparable performance.

- Lower Operating Costs: A remanufactured machine runs more efficiently, consuming less energy and requiring fewer repairs.

- Minimized Downtime: GCH Machinery’s expertise ensures faster turnaround times, reducing production delays.

3. Improving Reliability

GCH Machinery restores and enhances your Toyoda GL-6A for reliability. Their specialized service delivers:- Consistent Operation: With all components restored to peak condition, the machine operates smoothly, minimizing downtime.

- Extended Component Life: High-quality replacement parts ensure durability and reliability.

4. Adding Another Decade of Precision Grinding

Through GCH Machinery’s remanufacturing process, your Toyoda GL-6A can gain another decade of precise and efficient grinding. Benefits include:- Long-Term Productivity: Remanufacturing secures years of continued operation for your grinding machine.

- Sustainability: Extending the machine’s lifespan reduces waste and contributes to environmentally responsible practices.

5. Why Choose GCH Machinery?

GCH Machinery is renowned for its expertise in remanufacturing grinding machines, including the Toyoda GL-6A. Their team of skilled technicians ensures optimal results, offering precision, quality, and customer-focused solutions. By partnering with GCH Machinery, you gain access to cutting-edge upgrades tailored to your machine’s specific needs.

Conclusion

Remanufacturing is a smart and sustainable investment for manufacturers looking to maximize efficiency and longevity. With GCH Machinery’s expertise, your Toyoda GL-6A grinding machine can be restored to peak performance, saving money, improving reliability, and delivering another decade of precision grinding. Contact GCH Machinery today to begin your remanufacturing journey. Visit www.gchmachineryretrofit.com or call (586) 771-1500 to learn more. *Required fields

*Required fields

*Required fields

*Required fields

*Required fields

*Required fields

*Required fields

*Required fields