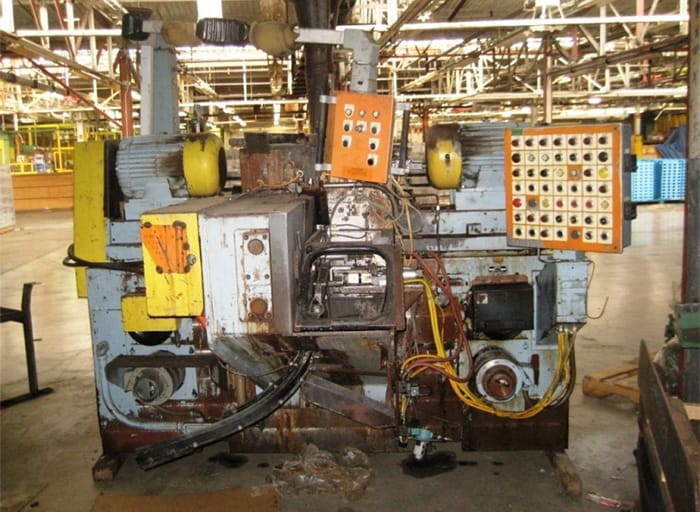

GCH Machinery Remanufactures Vintage Gardner Double-Disc Grinder for Global Bearing Manufacturer

A leading global bearing manufacturer needed to breathe new life into a mid-1980s Gardner double-disc grinding machine destined for a critical production line in Central Asia. The existing grinder, while originally a symbol of quality, required a complete remanufacture to meet the company’s stringent standards and achieve high-precision results.

Learn how GCH Machinery, celebrated for its expertise in grinding machine remanufacturing, transformed the vintage Gardner grinder.

BEARINGS COMPANY PUTS UPGRADED GRINDER BACK IN SERVICE FOR 4” BEARINGS (FACE GRINDING)

Gardner Double Disc

Reimagining the Grinding Process: A Multifaceted Approach

Our approach began with a thorough examination of the specific grinding application and the manufacturer’s requirements. This in-depth analysis allowed us to identify areas for improvement within the double-disc grinding process and pinpoint the necessary modifications to elevate the machine to an advanced level of functionality.

Following the comprehensive analysis, GCH embarked on a complete redesign of the Gardner grinder. This comprehensive remanufacturing process encompassed:

- Mechanical Systems: Upgraded mechanical components ensured smooth operation and enhanced part quality.

- Hydraulic and Pneumatic Systems: Modernized hydraulic and pneumatic systems optimized performance and efficiency.

- Lubrication and Cooling Systems: Redesigned lubrication and cooling systems minimized wear and tear while maintaining optimal thermal stability.

- Gaging Systems: Improved gaging systems facilitated precise measurement and control during grinding operations.

Unveiling Cutting-Edge Technology: Exclusive Upgrades by GCH Machinery

GCH Machinery further distinguished the remanufactured grinder by incorporating its proprietary advancements:

- New Servo Infeed: Enhanced accuracy in slide movement was achieved through the integration of a new servo infeed system.

- New Servo Dresser: A novel servo dresser simplified the machine’s structure and significantly improved the surface finish of the ground parts.

- THK Slides: The addition of high-quality THK slides contributed to superior work part quality, reduced downtime, and minimized vibration.

The Outcome: A State-of-the-Art Grinding Machine That Exceeded Expectations

The meticulous grinder remanufacturing for the bearing industry lead up to a cutting-edge grinding machine that surpassed the original equipment manufacturer’s (OEM) specifications. This revitalized grinder boasted the remarkable capability of maintaining tolerances within a single micron, a testament to the success of GCH Machinery’s remanufacturing expertise.

The machine experienced significant improvements, including:

- Restored Grinding Precision: The grinder regained its ability to produce parts with exceptional dimensional accuracy and surface finish.

- Reduced Vibration and Noise: The rebuild addressed the source of vibrations and noise, resulting in a smoother and quieter operation.

- Improved Efficiency: By incorporating upgrades, the grinder’s overall efficiency was enhanced, potentially leading to reduced production costs.

- Extended Machine Lifespan: The rebuild addressed potential failures and extended the grinder’s operational life, maximizing the return on investment.

Breathe New Life into Your Grinding Machines

Is your workshop burdened with aging grinding equipment? GCH Machinery‘s remanufacturing services can transform your legacy machines into high-performance assets. Explore our remanufacturing services or review other case studies to discover how GCH can unlock the full potential of your grinding operations. To learn more about our services, contact GCH today.

Contact Us

Request for Quote

Fields marked with an asterisk are required.