While purchasing a new machine might seem like the obvious answer, it’s not always the most practical or economical choice. Retrofitting precision grinders offers a smarter, more cost-effective path to revitalizing legacy equipment. A strategic retrofit can transform an aging grinder into a modern powerhouse, equipped with the latest technology and safety features.

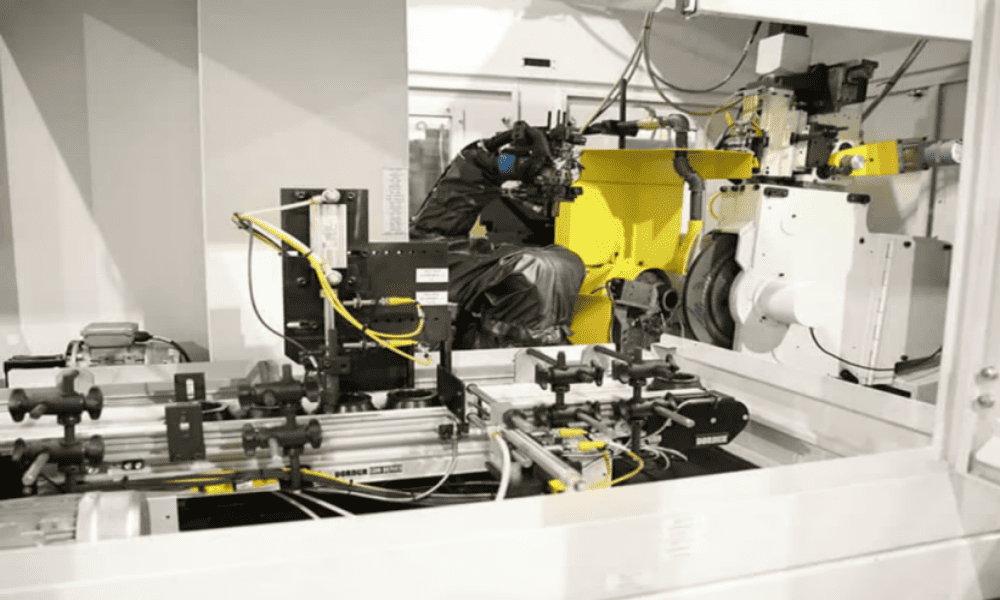

This deep dive will explore the benefits of grinder retrofitting for Landis OD grinders, outlining how GCH Machinery expertly revitalizes these machines to meet and exceed today’s stringent manufacturing standards.

The Cost of Running an Outdated Landis OD Grinder

Continuing to operate a legacy Landis OD grinder without necessary updates introduces significant risks and hidden costs that can impact your bottom line. These machines, while historically reliable, eventually show their age through performance degradation and safety concerns.Here are the primary challenges of relying on outdated equipment:

- Obsolete Parts: Finding replacement parts for older grinders becomes a difficult and expensive scavenger hunt. Scarce availability drives up sourcing costs and leads to longer lead times, extending machine downtime.

- High Downtime: As mechanical and electrical components wear out, breakdowns become more frequent and severe. Each production stoppage translates directly into lost revenue and can delay critical customer orders.

- Declining Accuracy: Worn guideways, aging spindles, and deteriorating Acme screws inevitably compromise the machine’s ability to hold tight tolerances. This decline in grinder accuracy and grinder precision results in higher scrap rates and inconsistent part quality.

- Operator Risks: Older grinders often lack modern safety features like interlocked guarding, emergency stops, and advanced sensor systems. This exposes operators to increased hazards and puts your business at risk of workplace accidents and compliance violations.

Why Retrofitting Your Landis OD Grinder Is the Smarter Path Forward

Instead of retiring a proven machine, a strategic retrofit offers a powerful alternative that blends performance with practicality. Grinder retrofitting is not just about replacing old parts; it’s about unlocking new potential from a familiar asset. It’s an intelligent investment that modernizes your equipment without the steep costs and operational disruptions of purchasing new.Here are the advantages:

- Extended Lifespan: A Landis OD grinder is built on a robust, durable casting. A retrofit preserves this solid foundation while upgrading critical components, maximizing the value and extending the operational life of a proven workhorse for years to come.

- Cost-Efficiency: The cost of a comprehensive retrofit is significantly lower than the price of a new machine. This allows you to achieve modern performance and capabilities while freeing up capital for other strategic investments.

- Operator Continuity: Your team is already familiar with the grinder’s fundamental operation and tooling. Retrofitting minimizes the learning curve and reduces extensive retraining time, allowing operators to adapt quickly to the new controls and features.

- Customization: Retrofitting allows you to add advanced OD grinder upgrades tailored to your specific production needs. Whether you need automation, advanced CNC controls, or specialized tooling, the upgrade can be customized to solve your unique challenges.

What a CNC Retrofit Delivers for Landis OD Grinders

A full CNC upgrade is one of the most transformative grinding machine upgrade solutions available. It breathes new life into a Landis OD grinder by integrating state-of-the-art technology that enhances every aspect of its performance, from speed and intelligence to precision and throughput.Next-Gen CNC Controls

Modern CNC processors dramatically increase processing speed, which reduces idle machine time and boosts overall production efficiency. User-friendly interfaces shorten the learning curve, empowering operators to program complex grinding tasks more quickly. Furthermore, smart alert systems can detect potential issues before they cause failures, minimizing unplanned downtime and preventing costly maintenance surprises. This proactive approach ensures better grinding consistency and machine reliability.Automation for Higher Throughput

Integrating automated part handling systems enables continuous, 24/7 “lights-out” grinding operations. This significantly reduces the need for operator intervention, which in turn lowers labor costs and improves workplace safety. Automation also ensures exceptional repeatability across long production runs, eliminating the variability and human error associated with manual loading and unloading.Restored Mechanical Precision

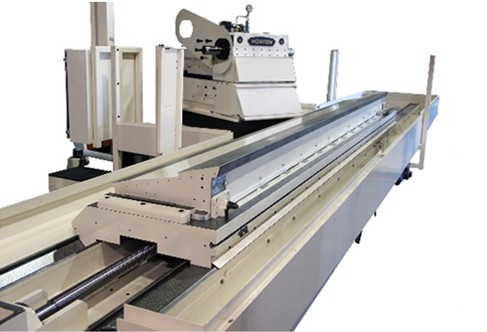

A retrofit is more than just an electrical upgrade. By restoring spindle rigidity and replacing worn components, we can eliminate chatter and significantly improve part surface finish. OD grinder upgrades like new anti-friction linear guide rails and precision ball screws coupled to Servo Motors with Encoder feedback enhance grinder accuracy and deliver smoother motion. Restoring the machine’s core geometry allows it to achieve sub-micron tolerances, bringing its performance back to—and often beyond—its original specifications.Productivity-Driven Enhancements

Modern enhancements directly boost productivity. In-process gauging systems provide real-time measurement, preventing scrap and ensuring every part meets exact specifications. High-performance wheel dressers and advanced wheel materials can increase grinding speed, improve surface finish, and allow for the grinding of tougher, more exotic materials.Step-by-Step: The Retrofitting Workflow

A successful retrofit is a well-planned and executed project. At GCH Machinery, we follow a meticulous, five-step process to ensure every machine is upgraded to the highest standard and aligned with your production goals, addressing any specific retrofitting grinder challenges you might face.Here’s an overview of the process:

- Step 1: Inspection & Evaluation: Our experts conduct a thorough evaluation of your grinder’s mechanical, electrical, and hydraulic systems to assess its current condition and identify key areas for improvement.

- Step 2: Planning: We collaborate with your team to select the right upgrades that match your production goals and budget. We then define the full scope of the project, covering all CNC, mechanical, and automation enhancements.

- Step 3: Execution: Our skilled technicians proceed with the retrofit, installing the new CNC upgrades, replacing worn components, and integrating modern safety systems to bring the machine up to current standards.

- Step 4: Commissioning: Once the installation is complete, we perform final calibration and testing to ensure the machine’s geometry is restored to “as-new” condition. We verify its precision and performance to guarantee it meets your requirements.

- Step 5: Training & Support: We provide comprehensive training for your operators and maintenance staff, along with detailed documentation. Our commitment continues with robust post-service support to ensure you get the most out of your newly retrofitted grinder.

Why Partner with GCH Machinery for Retrofitting & Rebuilding?

Choosing the right partner is critical for a successful grinder retrofitting project. GCH Machinery brings the following to every job:- Deep Experience: We are specialists with deep experience in Landis OD grinder upgrades. We understand the intricacies of these machines and know how to unlock their full potential.

- Turnkey Solutions: We offer complete turnkey solutions, handling all mechanical, electrical, and CNC aspects in-house. This integrated approach ensures seamless execution and a single point of accountability.

- Proven Results: We have a long history of delivering restored grinders that perform like new. Our commitment to quality ensures your retrofitted machine will be a reliable and productive asset for many years.

Unlock New Life & Precision in Your Grinder

In today’s competitive market, running outdated equipment is a risk you can’t afford. A strategic retrofit is a far more intelligent and cost-effective solution than buying a new machine, allowing you to achieve modern performance while maximizing the value of your existing assets. By upgrading your Landis OD grinder, you can boost productivity, improve grinder precision, and ensure a safer working environment.Unlock new life and precision in your grinder—talk to the GCH Machinery experts today!