Efficient, precise and modern machinery is crucial in today’s manufacturing landscape, where even the smallest inefficiencies can disrupt operations and increase costs. That’s why GCH Machinery specializes in remanufacturing industrial grinders, transforming outdated models into high-performing, state-of-the-art equipment.

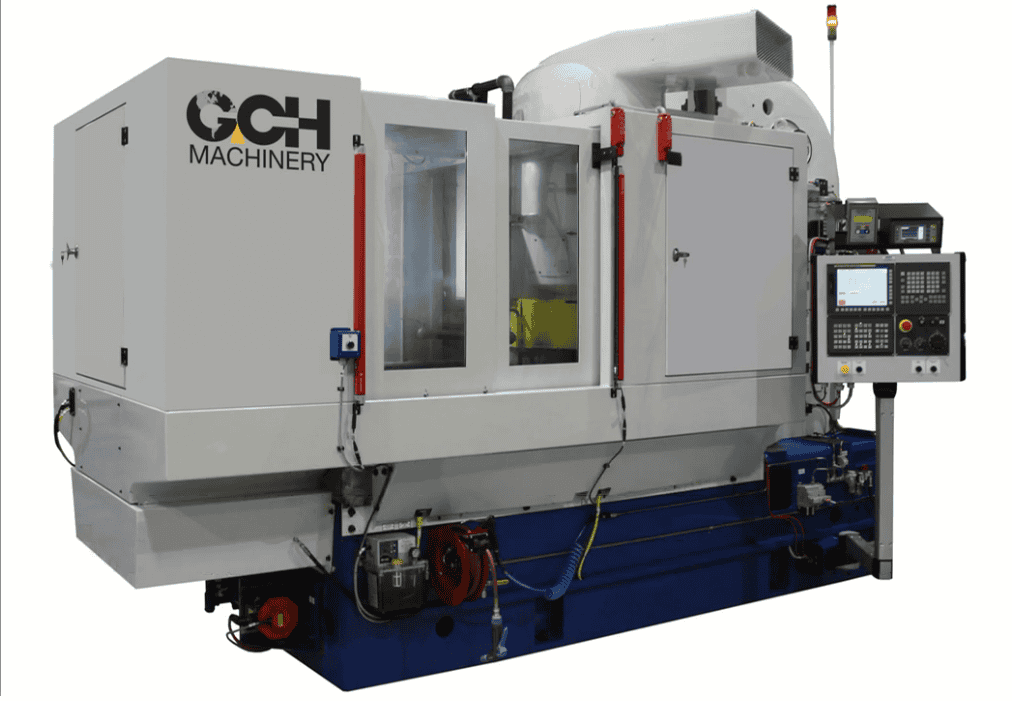

This case study explores how GCH Machinery remanufactured a Blanchard 32-60 grinder for refiner plates, revolutionizing its capabilities and showcasing the unmatched expertise of GCH Machinery in grinder remanufacturing.

The Purpose of this Case Study

The goal of this project was to convert an aging, tool room-style Blanchard 32-60 grinder into a highly efficient production grinder for manufacturing refiner plates. The transformation highlights GCH Machinery’s ability to rejuvenate outdated equipment, integrating advanced components and modern features to improve productivity, safety and part quality for manufacturers.

The Challenges of an Aging Blanchard 32-60 Grinder

Before the remanufacturing process, the Blanchard 32-60 grinder faced several operational and safety challenges, including:

- Obsolete control systems that severely impacted performance and reliability.

- Manual grinding operations that led to inconsistent output and compromised precision.

- Operational inefficiencies, resulting in costly downtime and high maintenance expenses.

- Lack of operator safety features, which posed potential risks to the workforce.

These challenges made it clear that modernization was necessary to ensure the grinder’s viability for production work.

Key Features of the Remanufactured Blanchard 32-60 Grinder

GCH Machinery brought the Blanchard 32-60 grinder back to life with a complete overhaul, integrating cutting-edge features that deliver precision, efficiency and safety. Below are the highlights of this transformation:

Enhanced Performance Components

- Neutrol Magnetic Chuck Control System: The newly installed Neutrol magnetic control system offers full adjustability, with magnetic force modifiable from 0–100%. This ensures tailored holding power for different part types and includes a built-in demagnetizer for smoother operations.

- SBS Acoustical Sensor: Feedback from this acoustical sensor improves grinding accuracy by monitoring the position and providing crash protection.

CNC Automation for Improved Efficiency

- Servo Table: Automates table movement, simplifying the loading of parts into grinding positions.

- CNC Dresser and Wheel Segment: Eliminates tricky manual processes, ensuring consistent and precise results.

- Servo Infeed Axis: Achieves unmatched precision by allowing exact control of the grinding wheel’s position.

- FANUCⓇ 35i Controls: Provides a reliable and user-friendly CNC system for precise, consistent machining.

- Custom-Designed HMI Screens: Intuitive screens make the operation seamless and easy to manage.

These advanced CNC upgrades significantly enhance productivity by reducing manual intervention.

Safety and Operator Protection

- Full Enclosure: Protects operators from potential hazards while shielding the machine from environmental elements.

- Light Curtains: Automatically halts operations if an object crosses a predefined safety boundary, ensuring risk-free machine operation.

Improved Maintenance and Durability

- Automatic Lubrication Systems: These systems ensure consistent lubrication, extending the grinder’s lifespan and reducing wear and tear.

- Coolant Filtration System: Keeps coolant clean with a magnetic and paper filtration unit, improving part quality and lowering maintenance costs.

- Mist Collector and Hose Reel: Enhances workspace cleanliness by removing coolant mist and facilitating quick clean-ups.

Electrical and Mechanical Upgrades

- New Electrical Panel: Substitutes obsolete electronics for increased reliability.

- Remanufactured 60” Magnetic Chuck: Features upgraded bearing surfaces and magnetic coils, enhancing its part-handling capabilities.

Compliance with Industry Standards

The updated grinder meets stringent CSA standards for safety and performance, ensuring compliance and reliability in a production environment.

Why Choose GCH Machinery for Blanchard Grinder Remanufacturing?

At GCH Machinery, we have over 1,500 successful remanufacturing projects under our belt, offering a proven track record of excellence. Here’s why businesses trust us:

- Turnkey Solutions: From initial consultation to final installation, all services are handled under one roof.

- Engineering Expertise: Custom solutions to meet unique client needs.

- Cutting-Edge Technology: Incorporation of the latest advancements in grinding technology.

- Precision and Quality: GCH Machinery consistently delivers equipment that meets the highest specifications for reliability and accuracy.

- Global Support and Maintenance: A worldwide service network ensures ongoing assistance and long-term satisfaction.

Benefits of Remanufacturing with GCH Machinery

Partnering with GCH Machinery doesn’t just upgrade your equipment—it transforms your entire production process.

- Improved Machine Performance: Advanced features increase precision, consistency and part quality.

- Cost Efficiency: Reduces maintenance expenses and provides a higher ROI compared to purchasing new machinery.

- Increased Productivity: Faster part cycle times and minimized downtime accelerate your operations.

- Operator-Friendly Features: User-friendly controls simplify setup and operation, further enhancing efficiency.

- Enhanced Machine Durability: Upgrades improve robustness and reliability, ensuring long-term performance capabilities.

GCH Machinery’s Expertise in Grinder Remanufacturing

With decades of experience and over 1,500 completed projects, GCH Machinery has established itself as a global leader in grinder remanufacturing. Our innovative solutions have helped countless organizations transform aging equipment into high-performing assets.

If your company’s grinding equipment is due for an upgrade, GCH Machinery can provide the quality, expertise and results you need to stay ahead.

Upgrade Your Equipment with GCH Machinery

Blanchard grinder remanufacturing for refiner plates is a specialized process that ensures precision and extended equipment life. Don’t settle for outdated machinery when a remanufactured grinder can deliver better performance, unbeatable ROI and long-term reliability.

Contact GCH Machinery today to discuss how our grinder remanufacturing services can transform your operations. Visit www.gchmachineryretrofit.com or call 586-771-1500 to learn more about grinder modernization.