Why Rebuild Instead of Replace?

When your grinder shows signs of wear—reduced accuracy, inconsistent output, or downtime due to failing components—you might assume a full replacement is the only option. But in many cases, centerless grinder rebuilding can restore your machine’s performance at a fraction of the cost of new equipment.

Benefits of rebuilding:

- Dramatically reduced capital expense

- Extended equipment life

- Customizable upgrades

- Improved precision and reliability

- Faster lead times than buying new

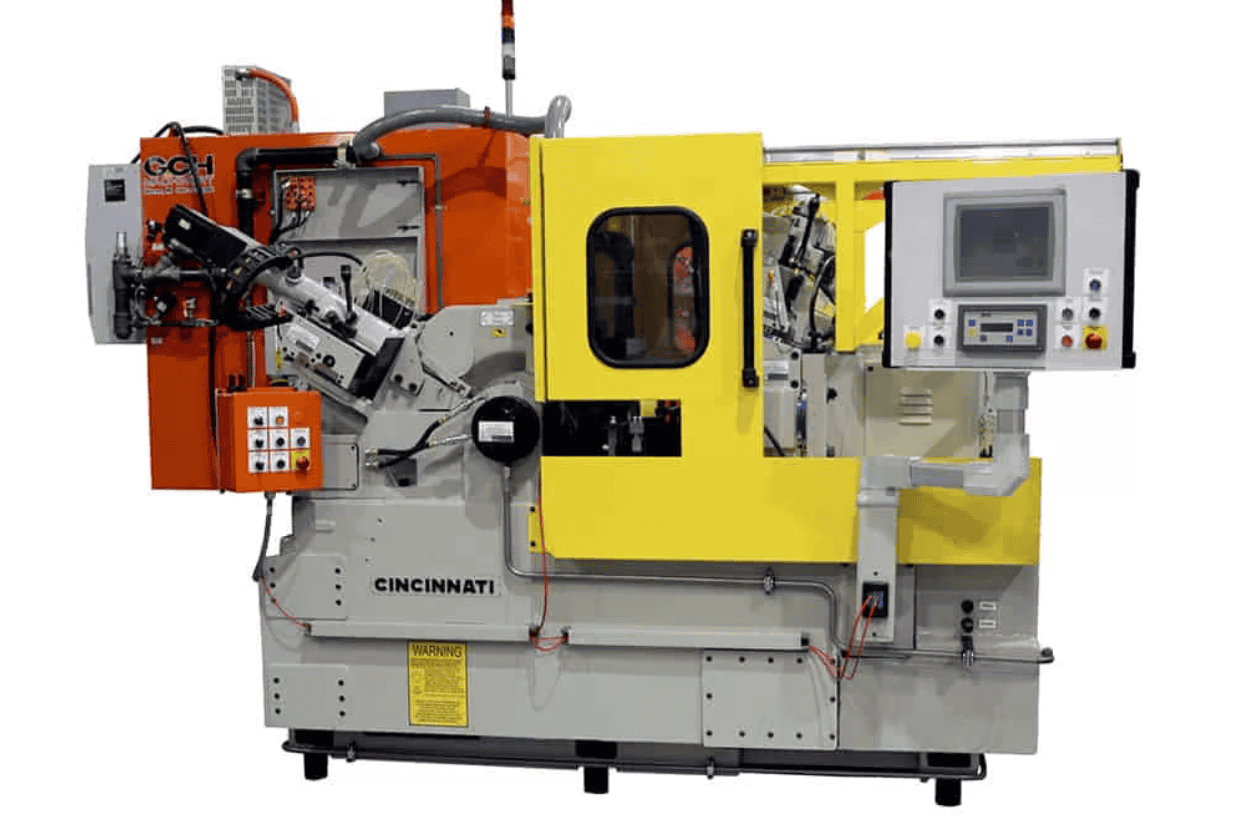

What Is Centerless Grinder Remanufacturing?

Centerless grinder remanufacturing goes beyond basic repairs or refurbishing. It’s a comprehensive overhaul—disassembling the entire machine, replacing or reconditioning components, and rebuilding it to meet or exceed OEM specifications.GCH Machinery Retrofit’s approach includes:

- Mechanical rebuild of all major systems

- Electrical system modernization

- Integration of CNC controls

- Safety upgrades

- Performance testing and quality assurance

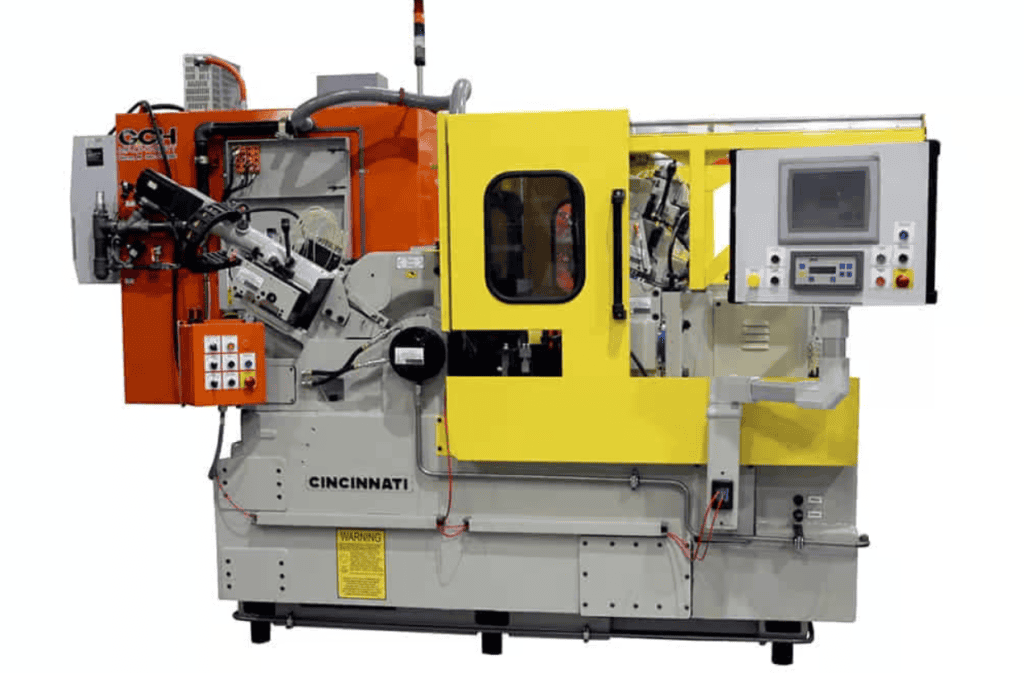

Adding Value Through Centerless Grinder Automation

Upgrading your rebuilt grinder with centerless grinder automation elevates your manufacturing capabilities. Automation not only boosts output and consistency but also reduces labor costs and minimizes human error.Common automation upgrades include:

- Automatic part loading/unloading

- Integrated gauging and feedback systems

- Servo-controlled dressing

- Robotic handling cells

Maximize ROI with a Smart Investment

Rebuilding and automating your centerless grinder is not just a technical upgrade—it’s a strategic business decision. By extending the life of your existing assets while modernizing them with automation, you’re maximizing efficiency and ROI without the high costs and long lead times of new machinery.Work with the Experts in Centerless Grinder Rebuilding

At GCH Machinery Retrofit, we’ve rebuilt and automated thousands of grinders across industries. Our experience, in-house engineering, and unmatched inventory of components mean we can deliver a turnkey solution tailored to your exact needs.Let us help you future-proof your operations with precision, reliability, and innovation. Request a quote or consultation today.

*Required fields

*Required fields

*Required fields

*Required fields

*Required fields

*Required fields

*Required fields

*Required fields